Introduction

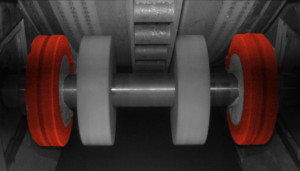

This case study examines the challenges and solutions associated with support wheels for potato elevator drums in a food processing environment.

Problem

A manufacturing plant was facing issues with support wheels for a potato elevator drum. This large drum, fully submerged in process water with potatoes being elevated to an upper-level process water flow, rotates on 2 shafts with 4 PU-covered wheels each. Due to a combination of high load, axial movement of the elevator drum (due to poor alignment), and the aggressive process water, the original PU covering failed. The polyurethane layer detached from the wheel hub within one month of operation. The original wheels were provided with axial grooves for the submerged application.

Solution

The proposed solution was to increase the layer thickness by 100% compared to the original, switch to polyurethane LUCANYL-HB 90°A, and apply one radial groove in the middle of the running surface. LUCANYL-HB 90°A is a polyurethane with high traction properties for the driving application and a high load-bearing capacity, combined with high resistance against hydrolysis—three critical properties for this application.

The radial groove in the middle of the running surface allows the axial movement of the elevator drum without causing high material stresses in the polyurethane layer. Although LUCANYL-HB 90°A is not the typical FDA-compliant polyurethane (for which LUCTHAAN polyurethanes would be recommended), it was accepted for this application due to its inert nature and lack of migration in submerged applications with direct food contact. The polyurethane covering was made in blue (detectable) due to the food application.

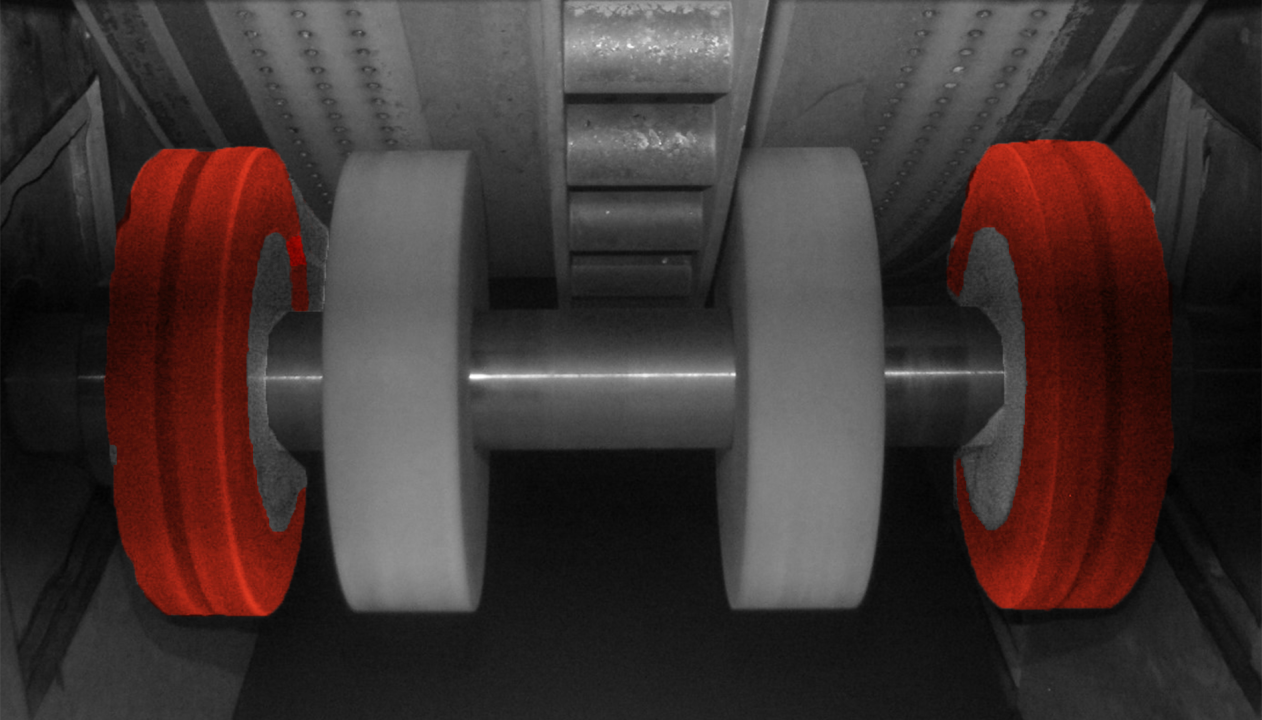

The original 4 PU-covered wheels on 1 shaft were replaced by 2 LUCANYL-HB 90°A wheels on the outsides plus 2 nylon wheels (with a smaller diameter) in the middle. The LUCANYL-HB 90°A wheels provide driving properties without slippage, while the smaller nylon wheels serve as a safety measure in case of extreme deflection due to peak loads in the elevator drum.

Results

The lifespan of the polyurethane covering increased from 1 month to more than 12 months, showcasing the effectiveness of the LUCANYL-HB 90°A solution.